Oily Water Separator

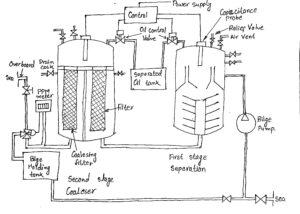

Draw and explain OWS operation.

#Oily Water Separator

-

- The separation of oil water in the separator takes place in two stages.

- In the first stage the separation is by gravity, whereas in the second stage the separation is by coalescing filters.

- The bilge pump delivers clean sea water to the first stage of the separator through the inlet valve.

- The vent is kept open till all the air is removed from the separator and water issues out.

- Oily water is delivered to the separator.

- As it enters through the inlet valve, oil separates by gravity and collects at the top of separator.

- The remaining oil sticks to the baffle plate as the water passes to the second stage.

- Oil droplets from the plate tends to travel upwards to the oil collection space.

- Oil from the top of chamber is automatically drained to the oil tank when the level reaches the bottom of the sensor.

- The oil drain valve from the top of the first stage separator is a diaphragm controlled piston valve.

#Oily Water Separator

-

- Control air is supplied to the diaphragm through a solenoid operated pilot valve.

- The capacitance probes senses oil quantity in the collection space and energizes the solenoid through the control switch.

- Water passes downward from the first to the second stage coalescer through a central pipe.

- The filter in the right chamber removes solid and some oil.

- Coalescing filter in the left chamber take out the remainder of the oil in the form of small droplets, which coalesce to form large drops.

- These rise to the oil collecting space.

- Oil content of the final discharge is below 15 PPM.

- In case the discharge of water after the second stage is more than 15 PPM, the monitor senses this and gives an audible and visual alarm in the engine room.

- At the same time, the monitor sends a signal to the three valve on the overboard discharge line, which closes the overboard and opens to the bilge tank.

#Oily Water Separator

- The sensor reverts to normal operation once the oil content drops below 15 PPM.

- The test cocks can be used to ascertain the levels of oil and water manually.

- A spring loaded valve is usually fitted on both discharges.

- However, it is essential that a relief valve be provided on the shell or incoming mixture line to prevent over pressure and accidental discharge to a confined space or prevent overboard and under working conditions.

- Such a relief valve should be preferably led back to the suction side of supply pump or to an overflow tank.

- The usual working pressure for the separator is in region of two bar, i.e. the pressure at which the spring loaded water discharge valve is set.

- The relief valve is set at about two and a half bar approximately.

#Oily Water Separator

For more click here

IMO website link click here